Biodegradable vs Compostable Food Packaging

The difference between biodegradable and compostable packaging may not be immediately obvious, but the underlying design philosophy and the impact on our environment are actually worlds apart.

Bio-what?!

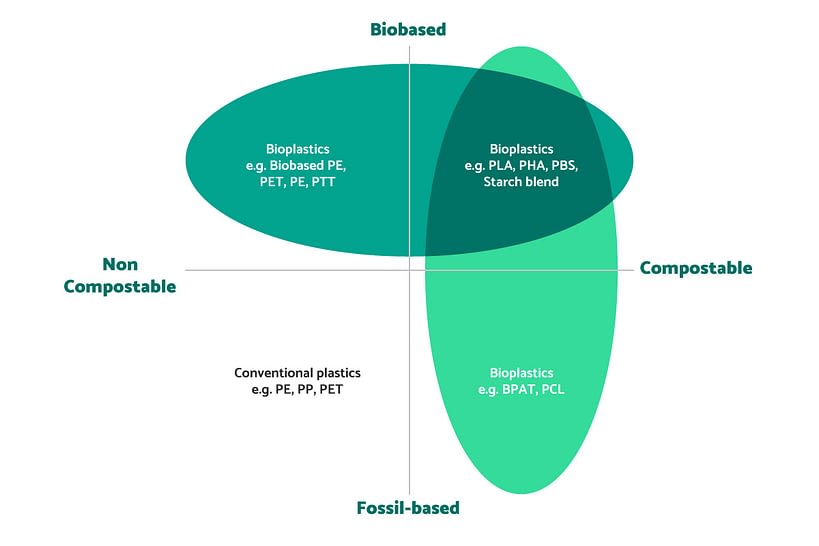

As the above graph illustrates, some plastics are derived from fossil fuels while others are made from plants. Plastics derived from plants are called bioplastics. A bioplastic isn’t automatically biodegradable or compostable. Some common plastics like PET (think water bottles) can be made from either fossil fuels or plants.

The term “biodegradable” is widely used to describe materials that can be broken down by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. However, no timeframe or conditions like the environment, the temperature or the level of moisture is implied or specified. That’s why “compostable” is a preferred term, as it is defined by stringent standards. Compostability can be measured and certified.

Compostable Plastic

Compostable plastic is designed to breakdown in an industrial or ‘hot compost’ where the conditions are carefully controlled to swiftly and completely break down the material and form nutrient-rich soil. This process is dependent on temperature and moisture levels being at the optimum for bacteria and microorganisms to break the material down. Food waste contamination will prohibit recycling options for most conventional plastics, but for compostable plastic breaking down in a compost environment, these additional inputs are beneficial.

Composting is a natural process, one that has been used by humans to turn unwanted organic waste into a valuable source of plant nutrients for thousands of years. The composting process harnesses the power of hungry microorganisms to eat and break down organic waste and promotes soil fertility and biodiversity.

Degradable Plastics

Sometimes called “biodegradable” or ‘oxo-degradable’ plastics, these are conventional plastics made with fossil fuels like PE, PP or PET which have a pro-oxidant additive. Hence, the ‘oxo’ in the name. It is this additive that allows the rapid degradation of the product into smaller fragments. The main action in this process is photodegradation, where the light from the sun acts upon the plastic, breaking it into smaller and smaller pieces. However, there is no independent verification or conclusive proof that the plastic will actually biodegrade, and this is a problem.

Degradable plastics are known to create microplastics as they break down and fragment, participating in a growing global issue that has direct health effects on the planet and us humans. They also contaminate conventional plastic recycling streams as they introduce additives that can make the end-product brittle.

In these ways, the sustainable claims for biodegradable plastics can be considered inaccurate, or at worst misleading. In fact, they have been banned in several countries, and most Australian states are in the process of phasing them out, too.

Why is Compostable Better?

1. Creates Nutrient-Rich Compost

While the material is not reconstituted in its previous state, as it might be with aluminium or glass recycling, compostable packaging, when composted with food waste, will live again as nutrient-rich, organic fertiliser: compost. Compost is known for its potential to sequester carbon and mitigate the impact of climate change.

2. Guaranteed to Break Down Within Regulated Timeframes

Products that are certified compostable have been thoroughly tested to ensure they break down in composting settings within regulated timeframes. For industrially compostable materials, such as compostable plastics, that is within 12 weeks at 55-65ºC, depending on the method used. For home compostable materials, such as fibre-based products, that can be 180 days, in the colder conditions typically found in home compost bins.

3. No Toxic Residues

Importantly, certified compostable materials are tested to ensure they do not produce any toxic residues that would contaminate the compost.

4. Part of the Circular Economy

Certified compostable materials, when used for certain applications such as foodservice or agriculture, are considered to be part of the circular economy. Adopting compostable packaging and developing dedicated compost collections can help close the waste loop.

5. Supports Local Recycling

The compost industry is well established so we are not starting from scratch. Opting for compostable packaging doesn’t require setting up new and expensive waste streams, or adding more trucks on the road. There is strong evidence using compostable packaging increases food waste collections, and less food waste in our landfill can reduce the impact of greenhouse gases that are released when organic materials decay in landfill conditions. So by choosing certified compostable products, you get the guarantee your waste will be swiftly turned into nutrient-rich compost and support local industry, avoid sending tonnes of plastic to landfill each year, limit the amount of plastic pollution in our environment, and help reduce greenhouse gas emissions to combat global warming.

See our range of sustainable Biopak products for all your takeaway and food packaging requirements

Republished with permission from www.biopak.com.au

As the winter approaches and the air starts to ...

The season of gratitude and celebration with fr...

In November 2022, it was announced Southern Hos...